SKID STEER CONCRETE MIXER ATTACHMENT | ETERRA

SKID STEER CONCRETE MIXER ATTACHMENT | ETERRA

Couldn't load pickup availability

ETERRA MIX AND GO SKID STEER CEMENT MIXER

Eterra's Mix & Go Skid Steer Concrete Mixer attachments allow you to scoop up material, mix it while you are on the move or while stationary. Save time and effort on your small-batch mixing needs with this rugged work-saving innovation from Eterra.

When you are ready to pour, you can discharge it with one of three methods (center chute, side trough, or hopper dump)

We offer 3 different sized models of Skid Steer Concrete to accommodate most standard skid steer loaders on the market today.

- BMX-250 is our small-medium sized unit, capacity is 9 cu.ft.

- BMX-450 is our medium-large sized unit, capacity is 16 cu.ft.

- BMX-600 is our large-sized unit, capacity is 21 cu.ft.

See It In Action Below

Skid Steer Concrete Mixer: Key Features

- 3 sizes available to suit your needs (9, 16, 21 cubic feet)

- Plenty of room to transport (with no spillage)

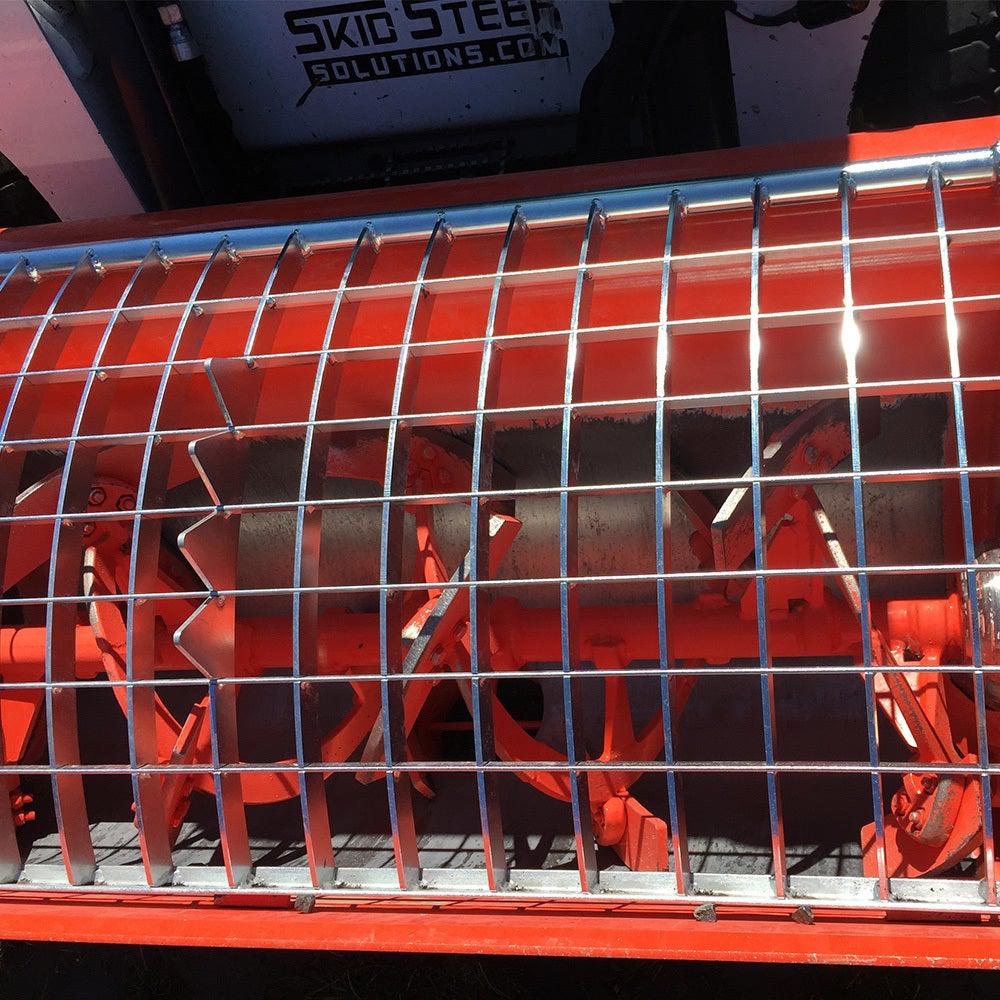

- Galvanized side chute and top inlet grate

- Hydraulically operated center discharge chute

- Spring-assisted side trough gate locks the gate in place

- The chain drive system is completely enclosed and sealed

- 5-foot flexible hose provided for easy pouring

- 8-inch diameter for bottom discharge chute

- Easy-lift grate makes cleanup a cinch

- Integrated bag cutter on inlet grate makes bag splitting painless

- Hardox 400 steel paddle/auger style drive is suitable for concrete and grout

- Precision laser cut parts, CNC forming and robotic welding ensures a high quality finished product

- Pad mounting holes for excavators to connect with, making this a dual-purpose product with just a few minutes and a wrench

- Drive system is reversible so that you can mix and dispense using your hydraulics

- Polyurethane seals with 90 shore hardness

Specifications

You can view the specifications for this product on our BMX Spec Sheet

Be Sure to Select Your Options Above

The Eterra BMX Skid Steer Concrete Mixer attachments allow the skid steer operator to control discharge for the center chute from inside the cab with the machine's auxiliary control system if installed. Please remember to choose your model and controller above when ordering.

Skid Steer Concrete Mixer Model

- 9 Cubic Feet | BMX-250

- 16 Cubic Feet | BMX-450

- 21 Cubic Feet | BMX-600

Attachment Controller Device

- Standard Switch Controls

- 14-Pin (Bobcat, John Deere, Kubota, Other)

- 8-Pin (Caterpillar, ASV, Terex)

- 7-Pin (Bobcat)

- None

How does a skid steer concrete mixer work?

A skid steer concrete mixer operates by harnessing the hydraulic power of a skid steer loader, commonly referred to as a skid steer or compact loader. Here's how it typically functions:

-

-

Attachment Connection: The skid steer concrete mixer is affixed to the skid steer loader via a universal quick attach mounting plate. This facilitates easy and rapid attachment and detachment.

-

Hydraulic Power: The hydraulic system of the skid steer loader drives the concrete mixer. The mixer incorporates hydraulic components like a hydraulic motor and hydraulic cylinder, which interface with the loader's hydraulic system.

-

Loading: The operator loads the mixer with the desired quantity of concrete mix, usually employing a front-end loader bucket or a similar accessory. The concrete mix may include ingredients like cement, sand, gravel, water, and other additives based on project specifications.

-

Mixing: Once loaded, the operator activates the hydraulic system to set the mixer in motion. The hydraulic motor propels a rotating drum or barrel inside the mixer, blending the ingredients to create a homogeneous concrete mixture.

-

Dispensing: Once the concrete is thoroughly mixed, the operator can manipulate the hydraulic system to tilt or rotate the drum, enabling the concrete to flow out through a chute or an opening at the bottom of the mixer. The concrete can then be poured directly into forms, molds, or construction sites as required.

-

Control and Adjustment: The operator has control over the speed and direction of the mixer drum rotation, as well as the rate of concrete discharge. This level of control ensures precise mixing and dispensing to meet specific project needs.

-

Maintenance: Routine maintenance of the skid steer concrete mixer is crucial to ensure optimal performance and durability. This includes cleaning the mixer after each use, inspecting hydraulic components for leaks or damage, and lubricating moving parts as necessary.

-

In essence, a skid steer concrete mixer offers a versatile and efficient solution for mixing and distributing concrete on construction sites, landscaping projects, and other endeavors where maneuverability and compact size are essential considerations.

How is the concrete dispensed?

Concrete is dispensed from a skid steer concrete mixer through a controlled process that allows for precise placement and distribution on the construction site. The dispensing mechanism is designed to efficiently transfer the mixed concrete from the mixer to the desired location, whether it's a form, mold, or directly onto the ground.

The dispensing process begins once the concrete has been thoroughly mixed inside the drum of the skid steer concrete mixer. The operator utilizes hydraulic controls to manipulate the mixer and guide the flow of concrete as it exits the machine. This ensures that the concrete is dispensed exactly where it's needed, minimizing waste and improving overall efficiency.

There are several methods for dispensing concrete from a skid steer mixer, including:

-

Chute Dispensing: In this method, the operator tilts the drum of the mixer to direct the flow of concrete through a chute attached to the bottom of the mixer. The chute allows for precise placement of the concrete, making it suitable for filling forms or molds with accuracy.

-

Side Trough Dispensing: Some skid steer concrete mixers are equipped with side troughs that facilitate the controlled discharge of concrete. The operator can adjust the angle of the trough to guide the flow of concrete to the desired location.

-

Hopper Dump Dispensing: In this method, the operator releases the concrete from the mixer by opening a hopper located at the bottom of the drum. The concrete flows out of the hopper and onto the ground or into a designated area.

Regardless of the dispensing method used, operators have full control over the flow rate and direction of the concrete, allowing for precise placement and distribution. This level of control ensures that the concrete can be dispensed efficiently and accurately to meet the requirements of the construction project.

Overall, the dispensing process of a skid steer concrete mixer is designed to be intuitive and user-friendly, allowing operators to effectively deliver concrete to the desired location with minimal effort and maximum precision.

How Much Concrete Can a Skid Steer Concrete Mixer Hold?

The capacity of a skid steer concrete mixer is a critical factor in determining its efficiency and suitability for various applications. Operators must consider the volume of concrete required for a particular job to ensure that the mixer can accommodate the necessary quantity. Having a mixer with an appropriate capacity helps optimize productivity and minimize the need for multiple mixing batches, thereby saving time and labor costs.

When selecting a skid steer concrete mixer, operators should carefully assess their project requirements and choose a mixer with a capacity that aligns with their needs. Factors such as the size of the construction site, the volume of concrete needed per batch, and the frequency of concrete mixing operations all play a role in determining the ideal capacity of the mixer.

The Eterra BMX 250 skid steer concrete mixer has a capacity of 9 cubic feet. This means it can hold approximately 0.33 cubic yards of concrete. The mixer is designed to accommodate small to medium-sized mixing needs, making it suitable for a range of applications on construction sites, landscaping projects, and more. With its compact size and efficient operation, the BMX 250 offers a convenient solution for mixing and dispensing concrete directly from a skid steer loader. Operators can easily load the mixer with the desired concrete mix using a loader bucket or similar attachment, and the hydraulic system of the skid steer powers the mixer's operation. Overall, the BMX 250 provides a reliable and versatile option for small-scale concrete mixing tasks.

The Eterra BMX 450 skid steer concrete mixer boasts a generous capacity of 16 cubic feet, equivalent to approximately 0.59 cubic yards of concrete. This increased capacity allows for larger batches of concrete to be mixed, making it suitable for medium to large-scale projects. With its robust construction and efficient design, the BMX 450 enables operators to complete concrete mixing tasks quickly and effectively. Whether on construction sites, landscaping projects, or other applications, this mixer offers versatility and reliability. Operators can load the mixer with the desired concrete mix using a loader bucket or similar attachment, and the hydraulic system of the skid steer powers the mixer's operation. Overall, the BMX 450 provides a convenient and practical solution for a wide range of concrete mixing needs.

How Much Hydraulic Flow Do I Need From My Skid Steer?

For both the Eterra BMX 250 and BMX 450 skid steer concrete mixers, the hydraulic flow requirements typically range from 15 to 30 gallons per minute (GPM) from the skid steer loader. This hydraulic flow is essential to power various functions of the mixer, including rotating the mixing drum and dispensing the mixed concrete.

The Eterra BMX 250, being a smaller-sized unit with a capacity of 9 cubic feet, may require a hydraulic flow rate closer to the lower end of the range, around 15 to 20 GPM, depending on factors such as the viscosity of the concrete mix and the desired mixing speed.

On the other hand, the Eterra BMX 450, being a medium-large sized unit with a capacity of 16 cubic feet, may benefit from a slightly higher hydraulic flow rate, ranging from 20 to 30 GPM, to ensure efficient mixing and dispensing of larger batches of concrete.

Adequate hydraulic flow ensures the effective performance of both mixers, facilitating precise mixing and dispensing of concrete for various construction and landscaping projects. It's crucial to refer to the manufacturer's specifications for each model to determine the exact hydraulic flow requirements and ensure compatibility and optimal operation with your skid steer loader.

How Much Do Skid Steer Concrete Mixers Weigh?

Skid steer concrete mixers vary in weight depending on their size, capacity, and design. Generally, skid steer concrete mixers weigh between 1,000 to 2,500 pounds. The weight of the mixer is a crucial consideration, as it affects the overall load capacity and stability of the skid steer loader.

The weight of a skid steer concrete mixer is influenced by factors such as the materials used in its construction, including steel for the drum and frame, as well as any additional components such as hydraulic motors and cylinders. Larger mixers with higher capacities tend to weigh more due to their increased size and materials.

It's essential to consider the weight capacity of the skid steer loader when selecting a concrete mixer attachment to ensure safe operation. Exceeding the weight capacity of the skid steer can compromise stability and safety, leading to potential accidents or damage to the equipment.

Overall, the weight of a skid steer concrete mixer is an important factor to consider when choosing the right attachment for a particular job or project. By selecting a mixer with an appropriate weight and capacity, operators can ensure safe and efficient operation on construction sites and other work environments.

Related Products

MINI SKID STEER CONCRETE MIXER | ETERRA

Questions & Answers

Have a Question?

-

Do you offer financing options for the concrete mixers?

Yes we do! You can find a link on the product page for the concrete mixers near the Add To Cart button.

-

How do you get the concrete out of the mixer when ready to pour?

The BMX mixers provide 3 different ways to pour concrete. You can use the attachment controller to open/close a gate for the center discharge chute (use with discharge tubing). You can also have a helper operate a manual gate on the side of the attachment for trough discharge. Finally, you can also dump the concrete out of the hopper with the machine for a bulk pour.

-

Do the BMX concrete mixer attachments require standard-flow or high-flow auxiliary hydraulics?

All of the BMX concrete mixers operate on standard-flow hydraulics, just be sure to choose the correct size for your skid steer. Give us a call if you need help deciding!

-

we're is it manufactuered?

Hi Rex, all of our products are manufactured in either the US or Canada. Thank you!

- Choosing a selection results in a full page refresh.

- Opens in a new window.